Battery performance can be significantly affected by extreme environmental conditions, such as high and low temperatures, humidity, and pressure variations. Understanding how to optimize battery performance under these conditions is crucial for ensuring reliability, longevity, and safety. This article provides insights and strategies to help you get the best out of your batteries, even in the most challenging environments.

Understanding the Impact of Extreme Conditions

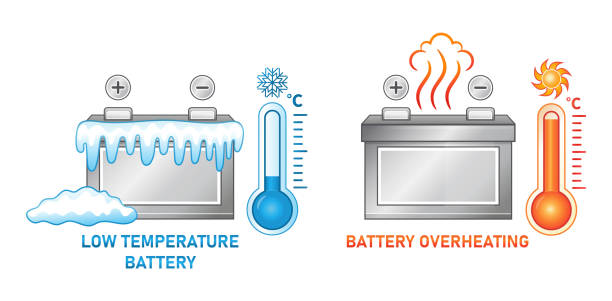

Temperature Extremes: High temperatures can cause batteries to overheat, leading to thermal runaway, reduced capacity, and shorter lifespan. Low temperatures, on the other hand, can increase internal resistance, reduce capacity, and slow down chemical reactions within the battery.

Low temperature and overheating battery icon set. Extreme cold and heat effect for accumulator.

Humidity and Moisture: Excessive humidity can lead to corrosion of battery components, short circuits, and leakage. Dry conditions can cause the battery materials to degrade more quickly.

Pressure Variations: Changes in atmospheric pressure can affect battery seals and lead to leaks, especially in sealed battery systems used in aerospace and underwater applications.

Strategies for Optimizing Battery Performance

Temperature Management Systems

Cooling Systems: Implement active cooling systems such as fans, liquid cooling, or phase change materials to dissipate heat in high-temperature environments.

Heating Elements: In cold conditions, use heating elements to maintain the battery at an optimal operating temperature, ensuring efficient performance.

Insulation: Proper insulation can help protect batteries from external temperature fluctuations, maintaining a stable internal environment.

Humidity Control

Sealed Enclosures: Use sealed enclosures to protect batteries from moisture and humidity. Ensure that these enclosures are equipped with desiccants or dehumidifiers to absorb any residual moisture.

Corrosion-Resistant Materials: Select materials that are resistant to corrosion for battery casings and connectors to prevent degradation in humid conditions.

Pressure Regulation

Pressure-Equalizing Vents: Utilize pressure-equalizing vents to manage internal pressure changes, preventing leaks and maintaining the integrity of sealed battery systems.

Reinforced Seals: Employ reinforced seals that can withstand pressure variations, especially in applications subjected to significant changes in atmospheric pressure.

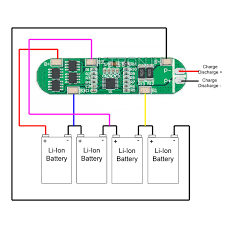

Advanced Battery Management Systems (BMS):

Real-Time Monitoring: Use a sophisticated BMS to continuously monitor temperature, voltage, and current. Real-time data allows for immediate adjustments to operating conditions, preventing damage.

Adaptive Control Algorithms: Implement adaptive control algorithms in the BMS to dynamically adjust charging and discharging rates based on environmental conditions, optimizing performance and extending battery life.

Optimized Charging Protocols:

Temperature-Compensated Charging: Adjust charging protocols based on the ambient temperature to prevent overcharging or undercharging. For instance, reduce the charging current in high temperatures to minimize heat generation.

Slow Charging in Extreme Cold: In extremely cold environments, slow down the charging process to allow the battery to warm up gradually and prevent internal damage.

Regular Maintenance and Inspection:

Scheduled Inspections: Regularly inspect batteries for signs of damage, corrosion, or leaks. Early detection of issues can prevent catastrophic failures.

Cleaning and Upkeep: Keep battery terminals and connections clean and free from debris to ensure optimal performance and reduce the risk of short circuits.

Practical Applications

Automotive Batteries: For electric vehicles (EVs) operating in extreme climates, integrate thermal management systems and ensure regular maintenance to keep the battery pack in optimal condition.

Renewable Energy Storage: In solar or wind energy storage systems deployed in harsh environments, use weatherproof enclosures and advanced BMS to maintain battery performance and longevity.

Aerospace and Marine Applications: Employ pressure-regulating technologies and corrosion-resistant materials for batteries used in aircraft and underwater vehicles to withstand extreme conditions.

Conclusion

Optimizing battery performance in extreme conditions requires a combination of advanced technologies, proper maintenance, and strategic design. By implementing effective temperature management, humidity control, pressure regulation, and sophisticated battery management systems, you can ensure that your batteries deliver reliable and efficient performance, even in the harshest environments. At MK ENERGY, we are dedicated to providing solutions that enhance battery resilience and efficiency, supporting your energy needs wherever you are.