In today’s world, batteries power countless devices and systems that are integral to modern life. Whether it’s the smartphone in your pocket, the electric vehicle on the road, or large-scale energy storage systems, batteries play a critical role in ensuring these technologies operate reliably and efficiently. However, with this growing reliance on batteries comes the need for rigorous testing and certification processes to ensure safety, performance, and regulatory compliance.

At MK ENERGY, we understand the importance of battery testing and certification. As a global leader in the research, development, production, and sale of lead-acid and lithium batteries, we recognize that these processes are essential not only for meeting industry standards but also for building customer trust and ensuring product longevity.

Why Battery Testing is Critical

Battery testing evaluates the performance, safety, and durability of batteries across various conditions and environments. This process involves subjecting batteries to a range of tests, including:

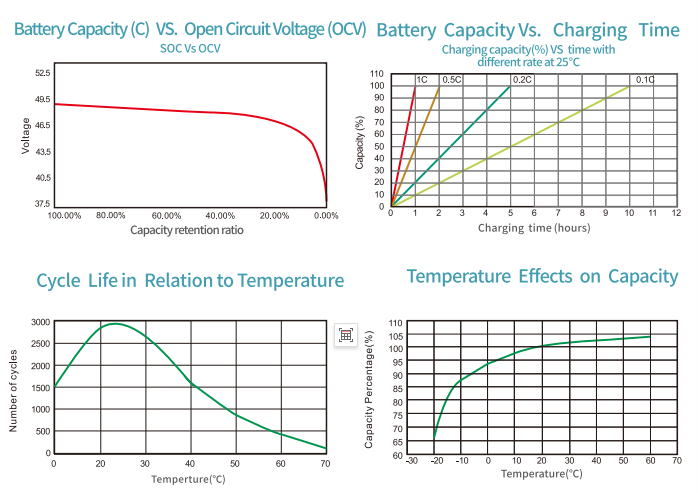

Performance Testing: Ensures that the battery delivers the required power and capacity across different load conditions.

Environmental Testing: Evaluates how the battery responds to extreme temperatures, humidity, vibrations, and shock, simulating real-world conditions.

Safety Testing: Identifies potential hazards like short-circuits, overcharging, or thermal runaway, ensuring that the battery is safe for end-users.

Cycle Testing: Measures the number of charge-discharge cycles a battery can complete before its performance degrades, helping manufacturers estimate the product’s lifespan.

By rigorously testing batteries in these ways, manufacturers can guarantee their products’ quality, which is critical for applications such as electric vehicles, energy storage systems, and medical devices where reliability is paramount.

The Role of Certification

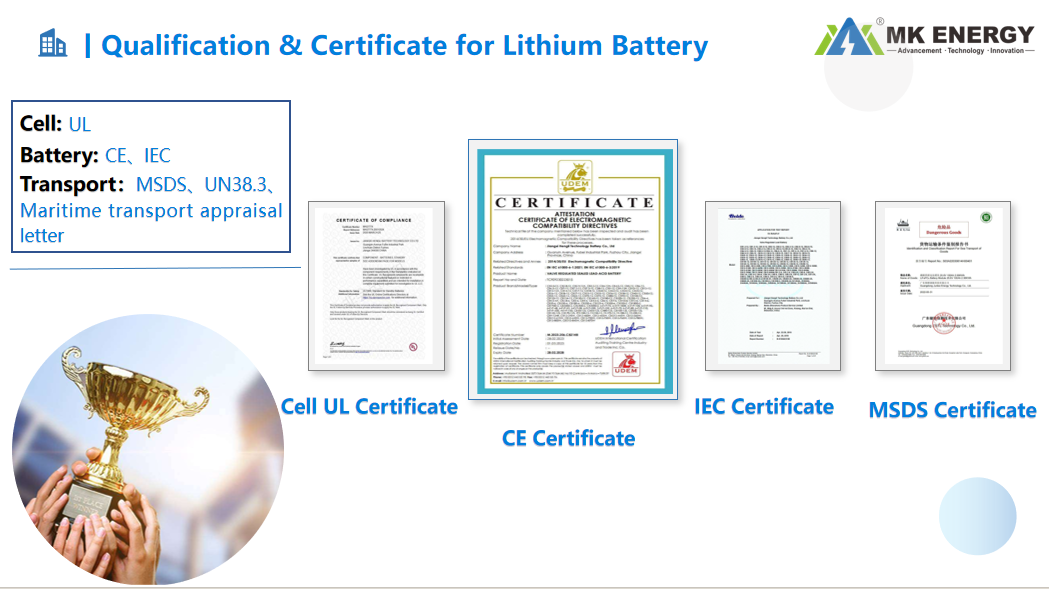

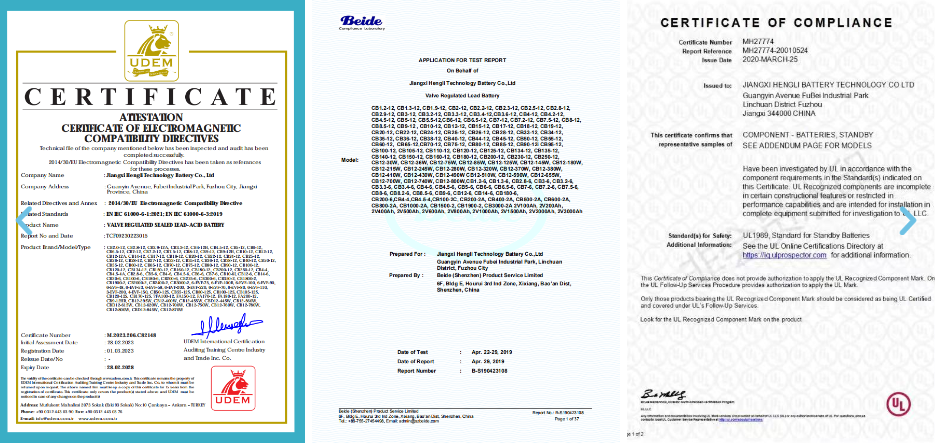

Certification goes hand-in-hand with testing. Once a battery passes the necessary tests, it must also meet specific international standards and regulations. These certifications ensure that the product complies with global safety and environmental guidelines. Some of the key certifications for batteries include:

UL: Ensures that the battery meets safety standards for electrical and fire hazards.

UN38.3: Ensures that lithium batteries are safe for transportation, including air, sea, and land shipments.

IEC Certifications: Assures that the battery conforms to international standards for performance, safety, and environmental impact.

RoHS: Confirms that the battery is free from harmful substances like lead, mercury, and cadmium.

These certifications are not just a formality; they are a critical part of the process to ensure batteries can be used safely in various applications, protecting both the environment and human life.

Benefits for Consumers and Businesses

Battery testing and certification offer significant advantages for both consumers and businesses. For consumers, certified batteries provide peace of mind that the product they are using is safe, reliable, and environmentally friendly. Certified batteries are less likely to fail, reducing the risk of incidents like battery fires or leaks.

For businesses, these processes are essential to avoid costly recalls, legal liabilities, or reputational damage. Moreover, many industries require specific certifications for products to be legally sold in their markets.

Conclusion

In a world increasingly reliant on battery power, rigorous testing and certification are not optional—they are necessary. At MK, we are committed to maintaining the highest standards in our lead-acid and lithium battery products. By prioritizing thorough testing and obtaining the necessary certifications, we ensure that our customers receive batteries that are safe, reliable, and built to last.

As we continue to innovate in the battery industry, we remain dedicated to ensuring our products meet the evolving demands of our global clients, backed by the utmost commitment to safety and quality.