The increasing demand for energy storage solutions across various industries has led to the growing importance of lithium battery technology. Lithium-ion batteries, known for their high energy density, longer cycle life, and efficiency, have become the preferred choice for many applications, from renewable energy storage to electric vehicles and backup power systems. However, one size does not fit all when it comes to energy storage. Every application has unique requirements, and a customized Batería de Litio pack is often the best solution.

This article explores how companies, like MK ENERGY, design and produce customized lithium battery packs tailored to meet specific energy storage needs, including factors such as energy density, working environment, cost considerations, and performance requirements. We will also look at case analyses to understand how tailored solutions can benefit different industries.

Understanding the Need for Customized Lithium Battery Solutions

The increasing adoption of lithium-ion batteries has highlighted the need for tailored solutions that maximize performance and efficiency. Customers often face a range of challenges that standard battery packs may not be able to address effectively. These challenges include:

- Energy Density: The amount of energy a battery can store in a given space and weight is crucial for many applications, especially those in mobile or space-constrained environments.

- Operating Environment: Temperature extremes, humidity, vibrations, and exposure to outdoor elements can impact battery performance. Custom designs can ensure that the batteries function optimally under specific environmental conditions.

- Cost Budget: Customers often have a set budget, and the customization must strike a balance between cost and performance while meeting the required specifications.

- Cycle Life and Durability: Different applications have varying demands for cycle life (how many charge/discharge cycles a battery can undergo) and durability. Some industries require batteries that can withstand thousands of cycles with minimal degradation.

Customizing lithium battery packs ensures that the final product meets the precise requirements for energy storage, longevity, and reliability in real-world conditions.

Key Factors to Consider When Customizing Lithium Battery Packs

Several key factors influence the design of customized lithium battery packs, and understanding these is crucial for creating an optimal solution.

Energy Density

One of the most important considerations when customizing a lithium battery pack is energy density. High energy density allows a battery to store more energy in a smaller and lighter package. This is particularly critical in applications like electric vehicles (EVs), drones, and portable power systems where space and weight constraints are paramount. By selecting the right chemistry (e.g., lithium iron phosphate (LiFePO4), lithium nickel manganese cobalt (NMC), or lithium cobalt oxide (LCO)), manufacturers can optimize the energy density to meet the specific energy requirements.

For example, a customer requiring a compact power supply for an electric vehicle may prioritize high energy density to maximize driving range while minimizing the weight of the battery.

Operating Environment

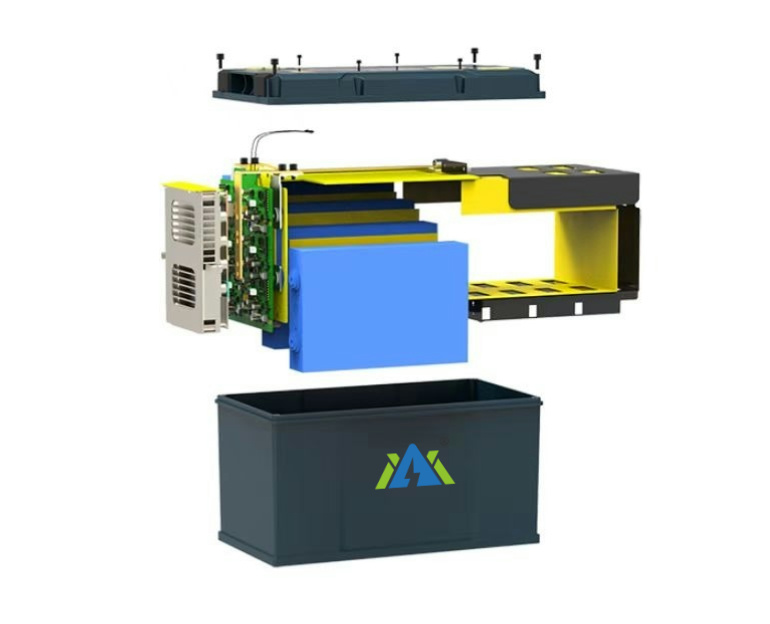

Lithium batteries must perform well under various environmental conditions, such as extreme temperatures, humidity, and vibrations. For instance, batteries used in outdoor applications, such as solar energy storage systems or industrial equipment, may need additional features like rugged casings, enhanced cooling systems, and protective circuitry to ensure safe and reliable operation.

A custom design might involve selecting specific components such as temperature sensors and thermal management systems that can maintain optimal performance in harsh conditions, ensuring the longevity of the battery pack.

Cost Considerations

Budget is a critical factor in battery selection, particularly for large-scale commercial projects. While lithium-ion batteries are generally more expensive than alternatives like lead-acid batteries, their superior performance, longer cycle life, and reduced maintenance costs make them a more cost-effective solution over time. When customizing battery packs, companies must strike the right balance between cost and performance by selecting the appropriate materials, chemistry, and features that meet both the customer’s requirements and budget.

For instance, a customer in a price-sensitive industry like telecom might opt for a slightly lower-energy-density battery chemistry like LiFePO4 for its balance of performance and cost-effectiveness.

Cycle Life and Durability

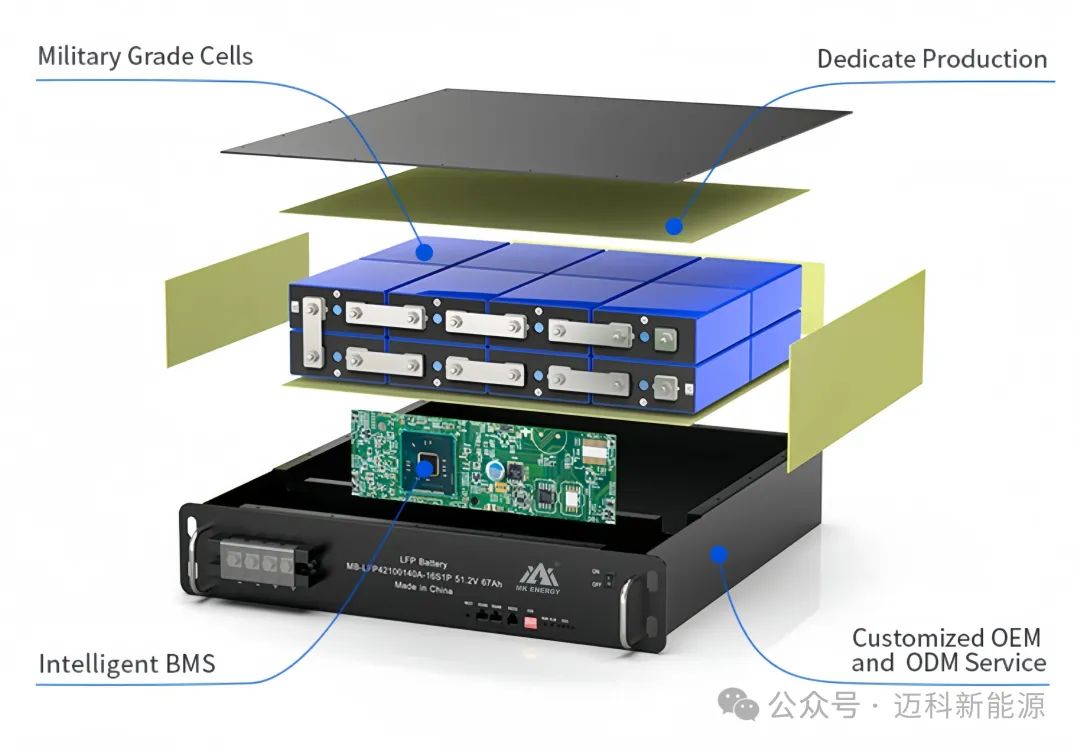

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity starts to degrade significantly. Customizing battery packs to optimize cycle life is essential for applications requiring long-term performance without frequent replacements. Advanced Battery Management Systems (BMS) can help maximize the lifespan of a battery pack by carefully managing charge cycles, temperature, and voltage.

For instance, energy storage systems used in grid applications or commercial buildings typically demand batteries that can endure thousands of charge cycles without significant capacity loss. By customizing the BMS and selecting high-performance lithium chemistries, manufacturers can ensure the battery meets the required cycle life.

Case Studies: Customized Lithium Battery Solutions in Action

Let’s explore a few real-world examples to illustrate how tailored lithium battery packs provide effective solutions for specific energy storage needs.

Case 1: Custom Lithium Battery Solution for Off-Grid Solar System

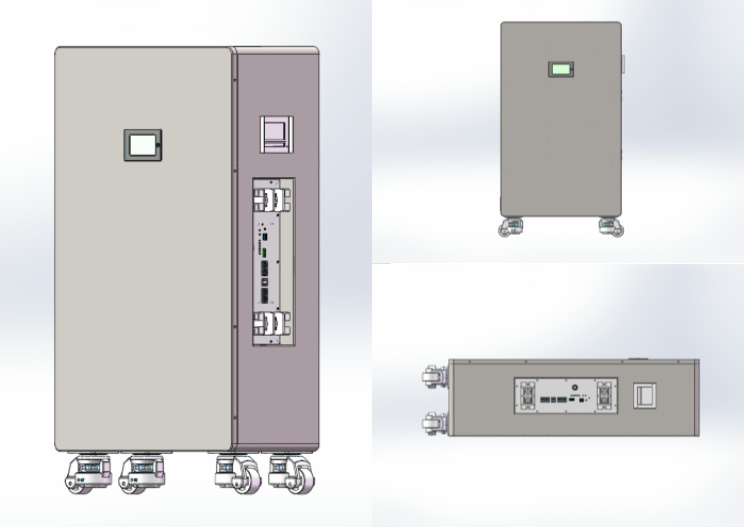

A solar energy company required a battery storage solution for an off-grid renewable energy system that would be installed in a remote area with extreme temperature fluctuations and harsh environmental conditions.

Customization Approach:

- Temperature Tolerance: The battery was designed using lithium iron phosphate (LiFePO4), which has a lower risk of thermal runaway and performs well in temperature extremes.

- Rugged Design: The battery pack was encased in a durable, weather-resistant shell to protect against physical damage from dust, moisture, and extreme weather.

- Battery Monitoring: A remote monitoring system was incorporated to allow for real-time performance tracking and maintenance.

Outcome:

The customized lithium battery pack successfully provided reliable energy storage for the off-grid system, maintaining high efficiency even in extreme environmental conditions. The robust design ensured long-term durability, and the remote monitoring system helped minimize maintenance costs.

Case 2: Customized Lithium Battery Solution for Industrial Equipment

A manufacturing company required a robust and long-lasting power solution for their industrial equipment, which operates in a vibration-prone environment. The battery had to withstand harsh working conditions while providing consistent power to run high-load machinery.

Customization Approach:

- Vibration Resistance: The battery was mounted in a shock-resistant casing to prevent damage from vibrations.

- Cycle Life: The customer needed a battery with a long cycle life, so a LiFePO4 battery was chosen, known for its durability and resilience in industrial applications.

- High Discharge Rate: The battery pack was designed to handle high discharge rates, ensuring that the machinery received adequate power during peak demand.

Outcome:

The customized lithium battery pack met the customer’s high power demands, with a long cycle life that minimized downtime and reduced maintenance. The shock-resistant design ensured that the battery could withstand vibrations, providing uninterrupted power for the industrial equipment.

Conclusión

Customized lithium battery pack solutions provide an essential service in industries where performance, efficiency, and durability are critical. By tailoring battery designs to specific energy storage needs, companies can offer solutions that optimize energy density, extend cycle life, enhance safety, and meet budget requirements. Whether it’s for electric vehicles, renewable energy storage, or industrial applications, customized lithium battery packs deliver the performance and reliability needed to keep operations running smoothly.

At MK ENERGY, we specialize in developing customized lithium battery packs that cater to a wide variety of energy storage needs. By working closely with our clients to understand their specific requirements, we deliver tailored solutions that help them achieve maximum efficiency and performance.