Lithium battery packs are at the heart of numerous modern technologies, powering everything from electric vehicles and consumer electronics to industrial energy storage systems. However, with their high energy density and widespread use, the safety of lithium battery packs has become a critical concern. While lithium batteries offer impressive performance, improper design, manufacturing, or handling can lead to safety risks such as overheating, short-circuiting, or even thermal runaway.

At MK, we recognize that safety is paramount in the development of Batería de Litio packs. Our commitment to safety is embedded throughout the entire lifecycle of our products—from design and production to rigorous testing procedures. By incorporating advanced safety features, using high-quality materials, and employing comprehensive testing protocols, we ensure that our lithium battery packs provide customers with both exceptional performance and peace of mind.

In this article, we will explore how safety is prioritized across all stages of lithium battery pack development and production, ensuring robust protection from design to testing.

Designing for Safety: Building Inherent Protection Mechanisms

The foundation of a safe lithium battery pack begins in the design phase. Thoughtful, proactive design choices can significantly reduce the risk of accidents and enhance the pack’s overall performance and longevity. At MK, we apply the highest standards in the design of our lithium battery packs, focusing on the following key safety considerations:

a. Battery Chemistry and Material Selection

The selection of safe, high-quality materials is the first step toward ensuring the reliability and safety of lithium battery packs. Not all lithium chemistries are equal—some offer better thermal stability, longer life cycles, and more reliable performance than others. For example, lithium iron phosphate (LiFePO4) batteries are known for their thermal stability and safer performance under high temperatures, making them a popular choice for applications requiring enhanced safety.

Furthermore, using high-grade anodes, cathodes, and separators ensures that the battery pack operates efficiently while minimizing the risk of short circuits or degradation over time. At MK, we only use premium-quality materials that have undergone thorough safety assessments and meet international standards.

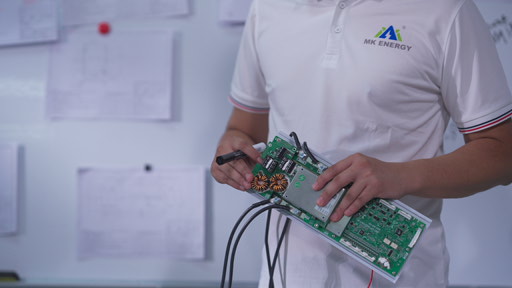

b. Integrated Protection Circuits

To prevent unsafe operating conditions, our battery packs are equipped with built-in protection circuits. These circuits include:

- Overcharge Protection: Prevents the battery from being charged beyond its safe voltage limits, which could lead to overheating or even rupture.

- Over-discharge Protection: Ensures that the battery is not discharged too deeply, which can cause permanent damage and reduce lifespan.

- Short Circuit Protection: Cuts off power if a short circuit is detected, minimizing the risk of fire or explosion.

- Temperature Control: Embedded temperature sensors monitor the battery pack’s temperature, shutting down the system if it becomes too hot to prevent thermal runaway.

These protective mechanisms are designed to safeguard the battery pack during normal operation and in the event of unusual circumstances, such as an accidental overload or external shock.

c. Robust Mechanical Design

The mechanical structure of a lithium battery pack plays an important role in preventing physical damage that could lead to internal short circuits or leakage. We ensure that our battery packs have robust enclosures that protect against external impact, vibration, and punctures, all of which could compromise the safety of the cells inside. Additionally, our battery packs are designed to withstand temperature extremes and environmental stressors, ensuring reliability in demanding conditions.

Production: Implementing Strict Quality Control and Manufacturing Standards

Even the safest designs can be compromised if not executed properly during production. At MK, we adhere to stringent quality control measures to ensure the highest standards are met throughout the manufacturing process. These steps include:

a. Precision Manufacturing Techniques

The production of lithium battery packs involves complex processes, including cell assembly, wiring, soldering, and integration with safety components. We use automated and precision-controlled manufacturing systems to ensure consistent quality and accuracy throughout the process. This precision reduces the risk of human error and ensures that each battery pack meets the highest safety standards.

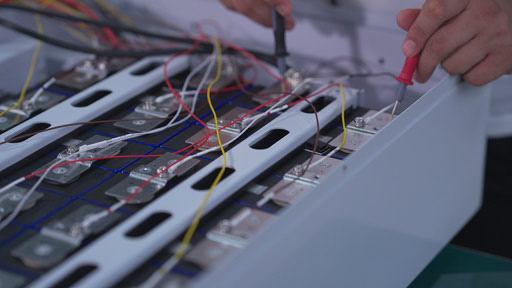

b. Cell Matching and Testing

One of the most critical aspects of lithium battery pack assembly is cell matching. Lithium-ion batteries are made up of individual cells, and it is essential that these cells are matched in terms of capacity, voltage, and internal resistance. If cells with mismatched characteristics are used together, they may discharge at different rates, leading to imbalances, overheating, or other safety issues.

We employ sophisticated equipment to test and match cells before they are assembled into a battery pack. This ensures that the battery pack operates as a cohesive unit, minimizing the risks of imbalances that could compromise safety.

c. Comprehensive Safety Integration

During the assembly of each battery pack, we integrate all the safety mechanisms that were designed into the product. This includes the protection circuits, thermal management solutions, and mechanical enclosures. Each safety feature is tested for functionality during assembly, ensuring that the final product meets the required standards for both performance and safety.

Testing: Rigorous Evaluation and Validation

The final stage of ensuring safety involves thorough and comprehensive testing. At MK, we conduct a series of rigorous tests on each lithium battery pack to validate its safety and performance under real-world conditions. These tests include:

a. Cycle Life Testing

We subject our battery packs to extensive cycle life testing, simulating years of use. This process involves charging and discharging the battery multiple times to assess how well it performs over time. This test not only evaluates the battery’s longevity but also checks that the safety features continue to function effectively throughout its lifecycle.

b. Stress and Safety Testing

Lithium battery packs are exposed to a range of stress tests designed to assess their response to extreme conditions. These include:

- Overcharge and Over-discharge Tests: We deliberately overcharge and over-discharge the battery to ensure that the protection circuits effectively prevent dangerous scenarios.

- Thermal Testing: The battery pack is subjected to high and low-temperature environments to ensure that it can operate safely under varying thermal conditions.

- Short Circuit Testing: We simulate short-circuit scenarios to confirm that the protection circuit responds quickly and safely, cutting off power before any damage or safety hazard occurs.

- Drop and Impact Testing: To evaluate the mechanical integrity, we drop the battery pack from various heights and impact it with force to ensure that the enclosure and internal components remain intact.

c. Certification and Compliance

We ensure that all of our lithium battery packs meet international safety standards and certifications, such as UL, CE, and RoHS. These certifications validate the safety, environmental, and electrical compliance of our products, giving our customers confidence in their reliability and safety.

Ongoing Monitoring and Feedback

The safety of lithium battery packs doesn’t end after production and testing. We continuously monitor the performance of our products in the field through customer feedback and in-use data. This helps us identify potential issues early and makes it possible for us to improve future iterations of our products. In the case of any safety concerns, we offer prompt support and solutions, reinforcing our commitment to customer safety.

Conclusión

At MK, we believe that safety should be at the core of every lithium battery pack we produce. From the initial design phase to final testing and beyond, we take every step necessary to ensure that our products are as safe as they are reliable. By using high-quality materials, incorporating advanced safety protection mechanisms, and subjecting our products to rigorous testing, we provide our customers with lithium battery packs that they can trust.

As the demand for lithium battery packs grows across industries, we remain committed to continuously improving our safety standards, giving customers the confidence that our products will perform safely and efficiently in any application. With our comprehensive approach to safety, we are confident that our battery packs will continue to power the future in a secure, sustainable manner.